Customize self-adhesive industry preferred supplier

From raw material procurement to final product delivery,our quality inspection process covers every link to ensure high-quality output throughout the supply chain.

Black PET Film Label Materials

| Feature | Description |

|---|---|

| Material Type | Opaque Black Polyester (PET) Film |

| Key Property | Excellent durability & high-temperature resistance |

| Surface | Smooth, ideal for high-quality printing (Matte/Gloss) |

| Primary Use | Durable labels for demanding industrial & premium branding |

A professional-grade pressure-sensitive material designed for challenging environments. Perfect for creating long-lasting labels in electronics, automotive, industrial, and premium product applications where resistance to heat, moisture, chemicals, and abrasion is required. Supports custom printing and die-cutting.

Product Description

Black PET Film Label Materials

Product Overview

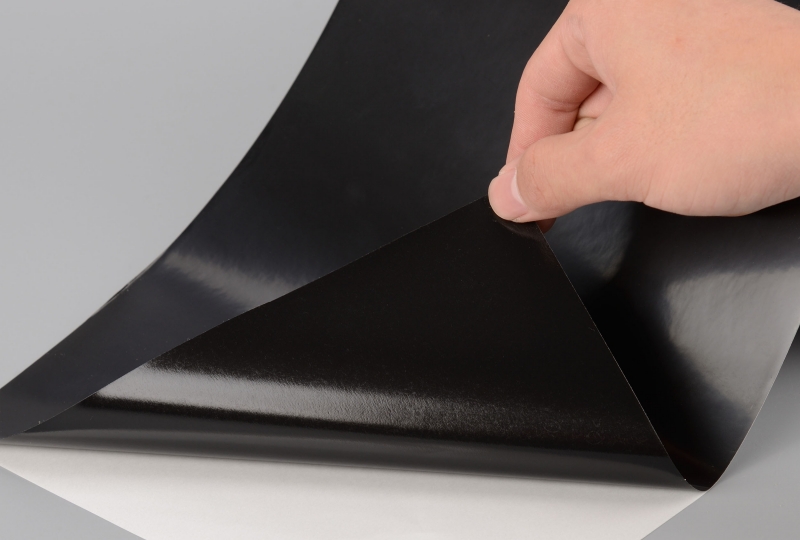

Black PET film is an advanced, pressure-sensitive label material renowned for its superior durability and sleek appearance. As a type of opaque black polyester film, it is engineered to deliver exceptional performance where standard labels fail. These black PET film materials are ideal for creating professional, long-lasting labels that withstand demanding conditions.

Core Characteristics & Advantages

-

Exceptional Durability: This material offers outstanding resistance to moisture, chemicals, abrasion, and tearing. It is the optimal choice for producing durable black PET adhesive labels that maintain integrity in harsh environments.

-

Superior Opacity & UV Resistance: The deep, uniform black coloration provides excellent light-blocking properties. This makes black polyester film labels perfect for protecting light-sensitive contents and ensuring print remains vibrant without fading from UV exposure.

-

High-Temperature & Dimensional Stability: With a wide operational temperature range, it exhibits minimal thermal shrinkage. This stability is crucial for high-temperature-resistant black PET labels used in automotive, electronics, and industrial settings.

-

Premium Printability: The smooth surface ensures excellent print quality with various techniques, allowing for sharp text, high-resolution graphics, and enhanced barcodes. This makes it a top substrate for premium black BOPET film labels.

Technical Data Sheet (Typical Values)

| Property | Specification |

|---|---|

| Face Material | Black PET Film |

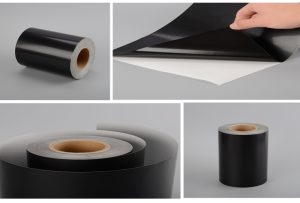

| Available Thickness | 50μm, 75μm, 100μm (Customizable) |

| Surface Finish | Matte Black / Glossy Black |

| Adhesive Type | Permanent Acrylic (Removable & Specialty options available) |

| Liner | White/Yellow Glassine or Kraft Paper |

| Temperature Resistance | -20℃ to +120℃ (Short-term peaks higher) |

| Key Certifications | Compliant with ROHS. UL recognition is achievable. |

Primary Industry Applications

-

Electronics & Manufacturing: Used for black PET film for electronic labels on circuit boards, components, and assets, requiring resistance to soldering heat and solvents.

-

Automotive & Industrial: Ideal for under-hood nameplates, part labels, and warning signs where weatherproof black polyester labels must endure oil, grease, and extreme temperatures.

-

Premium Branding & Packaging: Elevates the look of cosmetics, spirits, and tech gadgets with a luxurious feel. It is a key material for professional black film labeling solutions.

-

Outdoor & Asset Tracking: Provides durable, weather-resistant identification for logistics, equipment, and outdoor signage.

Why Choose GemmyLabel’s Black PET Film?

At GemmyLabel, we are experts in adhesive materials. We go beyond supplying film to provide true custom black PET label solutions.

-

Precision Material Selection: We help you select the exact combination of film grade, adhesive, and liner to match your surface and environmental challenges.

-

Reliable Quality & Consistency: Our rigorous quality control ensures every roll of our black BOPET film labels delivers consistent performance for smooth printing and application.

-

Full Customization Service: We offer comprehensive customization, including slitting, sheeting, and precision die-cutting to your exact dimensions and shape requirements.

-

Expert Technical Support: Our team provides end-to-end support, from sample testing to application advice, ensuring your labeling project is a success.

Request free material samples and technical data sheets to test for your specific application.