Specialty Adhesive Label — A Practical Guide for Buyers and Specifiers

Specialty adhesive label solutions are essential when ordinary stickers fail to meet the demands of harsh environments, complex supply chains, or strict regulatory needs. Whether you need a waterproof adhesive label for outdoor equipment, a tamper-evident adhesive label for pharmaceuticals, or a high-temperature adhesive label for appliances, choosing the right material, adhesive, and printing method can save time and cost while protecting brand integrity.

What Are Specialty Adhesive Label?

Unlike standard paper labels, specialty adhesive label materials are engineered for specific challenging applications where ordinary labels would fail. They consist of three key components: the face material (which can be anything from synthetic papers to specialized films), the adhesive (custom-formulated for different surfaces and conditions), and the release liner that protects the adhesive until application. This sophisticated construction enables them to perform reliably in situations that would cause conventional labels to peel, fade, or deteriorate.

Comprehensive Types of Specialty Adhesive Label

1. Durable Synthetic Labels

-

PET (Polyester) Labels: Known for their exceptional durability, PET adhesive labels offer excellent resistance to water, oils, chemicals, and abrasion. They maintain integrity in both high and low temperature environments, making them ideal for electronic components, automotive parts, and industrial equipment. PET labels come in various finishes, including transparent, bright gold/silver, and matte options.

-

PE (Polyethylene) Labels: Particularly valued for their flexibility and moisture resistance, polyethylene adhesive labels conform beautifully to irregular surfaces and squeeze containers. This makes them perfect for shampoo bottles, cleaning product containers, and other packaging that requires some give.

-

Synthetic Paper Labels: These specialized, durable adhesive labels combine the printability of paper with the durability of plastics. They withstand water, oil, and chemical exposure while remaining tear-resistant, ideal for outdoor applications, chemical containers, and products requiring long-lasting identification.

2. Security and Anti-Tamper Labels

-

Void and Destructible Labels: Engineered to break apart if removal is attempted, these security adhesive labels provide visual evidence of tampering. They’re crucial for high-theft items, pharmaceuticals, and valuable electronics where product integrity must be guaranteed.

-

Fragile Paper Labels: Designed with a special adhesive system that causes the face material to shatter upon removal attempts, these tamper-evident adhesive labels cannot be transferred to counterfeit products.

-

Holographic and Security Film Labels: Featuring custom holograms and specialized patterns, these anti-counterfeit adhesive labels provide both visual security and brand enhancement.

3. Specialized Adhesive Solutions

The adhesive component represents perhaps the most technical aspect of specialty labels, with formulations designed for specific surface chemistries and environmental conditions.

Table: Specialty Adhesive Types and Applications

| Adhesive Type | Technical Properties | Ideal Applications |

|---|---|---|

| Permanent | Forms an irreversible bond with the surface | Product identification, asset tracking, and warning labels |

| Removable | Clean removal without residue | Promotional pricing, temporary identification, and retail displays |

| Repositionable | Multiple applications without strength loss | Precision placement requirements, large format applications |

| Freezer-Grade | Maintains adhesion in sub-zero temperatures | Frozen food packaging, cold storage inventory, and pharmaceutical cold chain |

| High-Temperature | Resists curing, discoloration, or lifting under heat | Electronics manufacturing, engine components, and industrial processes |

Materials and construction: how performance is built

Specialty performance starts with facestock, adhesive, and liner choices. Common constructions:

-

Facestocks: coated paper, PP (polypropylene), PET (polyester), PVC — choose a durable adhesive label film when exposure to sunlight, oils, or abrasion is expected.

-

Adhesives: permanent, removable, high-tack, low-tack, acrylics, hot-melts — specify a high-tack adhesive label when bonding textured or oily surfaces.

-

Overlaminates and varnishes: UV, matte, gloss, or anti-scratch lamination creates UV-resistant adhesive label ideal for long outdoor life.

Understanding these layers helps buyers specify a chemical-resistant adhesive label or an industrial adhesive label that meets workplace needs.

Typical performance specs (quick reference table)

Below is a concise technical table with representative specifications used when comparing specialty adhesive label options. Values are illustrative; GemmyLabel provides exact test data on request.

| Property | Typical Range / Option | Common Use Case |

|---|---|---|

| Facestock | Paper / PP / PET / PVC | General, waterproof, extreme-durability |

| Thickness | 60–200 µm | Thin for thermal printers; thicker for durability |

| Adhesive Type | Acrylic, rubber, silicone | Permanent, removable, high-temp |

| Peel Strength | 0.5–8 N/25mm | Low for removables; high for industrial |

| Temperature Range | -40°C to +150°C (depends on adhesive) | Cold storage to oven labeling |

| Durability | 6 months–10+ years outdoor | Short-term vs lifetime applications |

| Print Methods | Flexo, digital, thermal transfer | Barcodes, high-res color, small runs |

| Special Features | Tamper-evident, RFID, holographic | Security, tracking, brand protection |

Industry applications and benefits

Specialty adhesive labels serve sectors where reliability equals compliance:

-

Logistics & warehousing: thermal transfer adhesive labels for barcode longevity and scan accuracy.

-

Food & beverage: food-safe adhesive labels with FDA-compliant inks and adhesives.

-

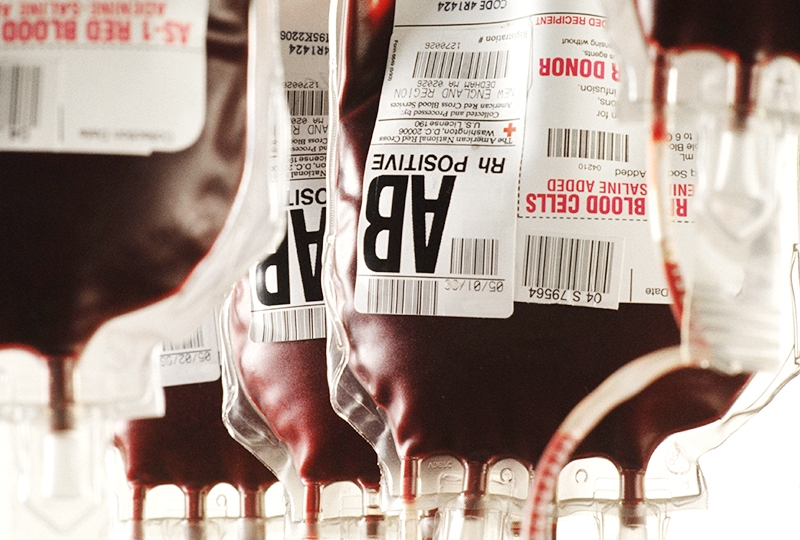

Pharmaceuticals & medical devices: tamper-evident adhesive labels and serialized labels for traceability.

-

Electronics & appliances: high-temperature adhesive labels resistant to reflow and washing processes.

-

Chemical and industrial: chemical-resistant adhesive labels that survive solvents and oils.

Each use case benefits from tailored material selection, which reduces returns, enhances traceability, and protects reputation.

Design and print considerations

Good label performance starts in design. Use these practical tips:

-

Match facestock and adhesive to substrate (plastic, glass, metal, corrugated fiberboard) to avoid delamination of your adhesive label.

-

Choose appropriate print resolution and ink type for applications: wax-resin ribbons for abrasion resistance, resin for chemical resistance — vital when ordering abrasion-resistant adhesive labels.

-

Include bleed, quiet zones, and barcode verification tolerances to ensure scannability of barcode adhesive labels in automated environments.

How to evaluate suppliers: technical and logistical checks

When selecting a supplier for specialty adhesive label orders, assess:

-

Materials testing: ask for peel tests, aging, solvent, and temperature data — required for certifying industrial adhesive labels.

-

Print capability: in-house flexo, digital, and thermal production for both short runs (custom adhesive labels) and large batches.

-

Quality control: ISO audits, barcode verification, batch traceability — particularly important for medical adhesive labels.

-

Lead times and MOQ: ensure your supplier supports your inventory flow with appropriate minimum order quantities for custom adhesive labels.

Why choose GemmyLabel?

GemmyLabel combines technical know-how with manufacturing flexibility. We offer:

-

Full-material consultation to specify the correct waterproof adhesive label, removable adhesive labels, or security adhesive label for your application.

-

In-house printing (digital, flexo, thermal transfer) to produce both short-run custom adhesive label and high-volume orders with consistent color and barcode quality.

-

Testing and certification support — peel strength reports, temperature tables, and sample trials — so you buy the right adhesive label the first time.

-

Responsive customization: variable data, RFID integration, custom die-cut shapes, and on-demand prototypes for approval.

Custom services and ordering with GemmyLabel

GemmyLabel supports full customization: artwork assistance, material sampling, pre-production proofs, and small-batch trials. Workflows include:

-

Material recommendation and sample dispatch for high-temperature adhesive labels and chemical-resistant adhesive label.

-

Prototype runs and in-line testing for tamper-evident adhesive label and serialized product labeling.

-

Flexible finishing options (lamination, varnish, hot-foil) to add durability or security features to your brand adhesive labels.

Choosing the right specialty adhesive label — a checklist

Before ordering, cross-check:

-

Substrate surface and condition: select a high-tack adhesive label if the surface is uneven.

-

Environmental exposure: moisture, UV, chemicals; prefer UV-resistant adhesive labels for outdoor use.

-

Required lifetime and removability; choose removable adhesive labels for temporary promotions.

-

Print and barcode needs; request barcode verification for thermal transfer adhesive labels.

-

Regulatory or safety requirements; confirm compliance for food-safe adhesive labels or medical applications.

Conclusion

Specialty adhesive label choices have a direct impact on product safety, regulatory compliance, and brand perception. By understanding materials, adhesives, and printing methods — and by partnering with a supplier like GemmyLabel that offers testing, customization, and small-batch capability — you reduce risk and improve operational efficiency. Suppose you need help choosing between waterproof adhesive labels, tamper-evident adhesive labels, or other specialty types. In that case, GemmyLabel can provide samples, technical datasheets, and a tailored quote to meet your exact requirements.