Synthetic Paper Labels: Durable, High-Performance Solutions for Manufacturers

In modern manufacturing and logistics, labels must do more than look good – they must survive tough conditions. Synthetic paper labels (also called film labels) deliver exactly that. Made from durable plastic-like films (such as polypropylene or polyester), these labels combine the look and feel of paper with rugged strength. In other words, they behave like paper in printing and appearance, but resist damage like a plastic film. This makes synthetic labels ideal for industrial and outdoor applications where moisture, chemicals, heat, or abrasion would ruin ordinary paper. In fact, manufacturers widely choose synthetic paper and film labels for products that need long-lasting, waterproof identification.

Exceptional Durability and Environmental Resistance

Synthetic paper labels outlast regular paper in any harsh environment. Their polymer substrate is inherently waterproof and weatherproof, so labels stay intact on refrigerated, wet, or oily surfaces. For example, film-based synthetic labels “are highly resistant to water, chemicals, and abrasion,” ensuring they endure spills, solvents, and rough handling without tearing. Unlike wood-pulp paper (which swells, tears, and fades when wet or exposed to UV light), high-grade synthetic materials maintain adhesion and legibility. They even survive extreme temperature swings: polyester (PET) synthetic labels can withstand continuous exposure to roughly 300°F (150°C), while polypropylene (PP) labels remain stable in cold conditions. In practice, this means a synthetic barcode on a car engine part or an electronics component will stay readable after heat, chemicals, or abrasion tests. In short, synthetic labels protect your product information from the elements.

-

Waterproof & Chemical-Resistant: Synthetic paper labels are inherently moisture-proof. They repel water, oil, and many chemicals that would blur or dissolve standard paper labels.

-

Tear & UV Proof: With a polyester or polypropylene base, these labels are tear-resistant and won’t yellow or crack under sun exposure. They survive long-term outdoor use or repeated handling.

-

Heat-Stable Adhesion: Specialized acrylic and rubber adhesives on synthetic labels maintain grip at high temperatures. The label won’t curl, lift, or peel even in hot or cold production environments.

-

Durability in Action: For example, synthetic oil-and-sauce bottle labels resist grease and moisture for their entire lifecycle. In glass or metal manufacturing, where furnaces exceed 400°F, synthetic labels stay legible and affixed throughout the process.

Superior Print Quality and Customization

Despite their toughness, synthetic paper labels do not compromise on printability or appearance. The smooth plastic surface yields sharp, high-resolution printing. In fact, the coating on synthetic stock holds ink better than paper, preventing smudges or fading. Barcodes, graphics, and small text come out crisp and clear – a critical advantage for tracking and branding. One manufacturer notes that synthetic paper delivers “vibrant and crisp print quality” and “excellent clarity” for logos and codes.

Customization is also easier with synthetic film. These labels can be die-cut into any shape or size, from tiny asset tags to large equipment labels. Coatings allow finishes like gloss, matte, or UV varnish to meet branding needs. You can even choose adhesives (permanent, removable, high-tack, etc.) to suit the surface and lifespan required. For example, GemmyLabel’s synthetic paper for “water labels” has a special surface coating optimized for flexographic and letterpress printing, plus a high-tack, food-grade glue. All of this means your design comes through vividly, and your label stays durable.

-

Crisp Imaging: Synthetic paper’s coating yields higher ink saturation and better color reproduction than regular paper. Logos, brand colors, and photographs look sharper.

-

Fine Detail: Barcodes and QR codes print clearly and resist scratching. This ensures scans remain reliable even after long-term wear.

-

Design Flexibility: Materials can be cut to custom shapes and finished (glossy, matte, etc.) without losing durability. This allows unique labels for electronics, automotive, or medical products that still endure manufacturing environments.

Common Synthetic Materials and Properties

Not all synthetic papers are identical – manufacturers choose between different films based on need. Below is a summary of popular synthetic materials:

| Material | Key Properties | Typical Uses |

|---|---|---|

| Polyester (PET) | Plastic-like durability and stiffness. Highly tear-resistant and rugged. Excellent heat and chemical resistance. | Durable goods labels (e.g., electronics, automotive parts), outdoor equipment tags, ID cards. |

| Polypropylene (PP) | Lightweight, excellent moisture and UV resistance. Smooth matte or gloss finish, ideal for color printing. | Shipping labels, packaging tags, retail and food packaging (condensation-proof), and signs. |

| Vinyl (PVC) | Heavy-duty, glossy finish. Extremely water and oil-resistant. Remains intact under harsh weather. | Outdoor signage, banner labels, and industrial equipment tags. (PVC is less eco-friendly, so often used in long-term applications.) |

Each material can be coated (coated, uncoated, or double-coated) to optimize printability. For instance, top-coated synthetic paper provides exceptional ink adhesion for UV printing. In summary, choosing the right film ensures you get the needed strength and compatibility with your printing process.

Versatile Applications Across Industries

Because of their resilience, synthetic labels are finding uses in almost every sector. They excel wherever labels are exposed to moisture, chemicals, abrasion, or extreme conditions. Examples include:

-

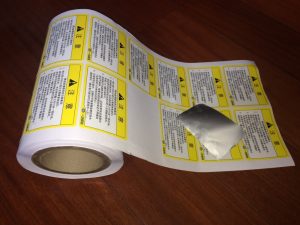

Chemical and Industrial Products: Drum and machine part labels survive exposure to solvents and oils. Manufacturers of paints, cleaners, and lubricants rely on synthetic labels for compliance and tracking, since paper labels would fail in those environments.

-

Food & Beverage Packaging: Bottles, jars, and frozen foods use synthetic labels because they resist condensation and refrigeration. (Alcohol-resistant adhesives and FDA-compliant materials like those GemmyLabel uses ensure safety on food-contact surfaces.) Wine, beer, and sauce bottles often carry waterproof synthetic labels that remain perfect in freezers and ice buckets.

-

Pharmaceuticals and Healthcare: Synthetic tube and vial labels survive sterilization, alcohol exposure, and refrigeration. Medical devices and lab samples require labels that won’t smear or fall off under sanitizing or extreme cold. Synthetic materials meet these needs where paper cannot.

-

Automotive and Electronics: Components that get painted, cleaned, or handled heavily need durable labels. Synthetic polyester tags resist high heat from engines or ovens; synthetic polypropylene labels stick to plastic housings and metal parts without peeling.

-

Logistics & Asset Tracking: Barcode labels on pallets, shipping containers, or warehouse racks endure bumps, moisture, and temperature changes. Synthetic labels ensure inventory barcodes stay scannable in warehouses or outdoor yards.

In short, any application demanding longevity benefits from synthetic paper labels. A synthesis of case studies even highlights examples like oil and sauce bottles (labels resist grease and condensation) and industrial warning labels (clear in extreme heat and chemicals).

Environmental Performance and Compliance

While traditional paper is fully recyclable and biodegradable, modern synthetic labels can also be made with sustainability in mind. Many synthetic stocks (PP and PET) are fully recyclable plastics. For example, polypropylene synthetic paper can be recycled and reused without harmful waste. Some companies now even offer bio-based PE or PP films (made from plant resins) to reduce petroleum use. Plus, synthetic paper production uses no trees and minimal water, and certain grades are chlorine-free. All told, synthetic labels can support eco-friendly goals: they last longer (less frequent replacement), and many films are recyclable.

Compliance is another strength. Manufacturers like GemmyLabel offer food-grade synthetic labels. For instance, their “water label” synthetic paper meets EU (EC 1935/2004) and FDA (175.105) food-contact standards. This means you can use these labels on bottles or containers that touch food or beverages. GemmyLabel also formulates adhesives (high-cohesion, acrylic or rubber-based) that won’t break down on plastics or glass in high-speed lines. In regulated industries (food, pharma, chemicals), you get durable labels that also meet safety regulations.

Why Choose GemmyLabel for Synthetic Paper Labels?

GemmyLabel specializes in serving manufacturers with custom synthetic label solutions. Here’s why customers rely on us:

-

Full Customization: We tailor every aspect of your synthetic labels. Our team will work with you on material (PP, PET, PVC, etc.), label thickness, shape, and specialized coatings or laminates. Whether you need a glossy food label or a matte machine tag, we can design it. Every size, color, adhesive, and finish can be customized to fit your production line.

-

Quality at Every Step: From raw material procurement to final delivery, we implement strict quality inspections. Each roll or sheet of synthetic label stock is checked for consistency. Our production follows ISO standards, ensuring each label meets the promised specifications. This means no weak spots or defects in your labels – you get reliable performance batch after batch.

-

Industry Expertise: GemmyLabel’s experience spans dozens of sectors. We understand harsh environments: our labels have been tested for adhesion on oily pipes, clarity in UV light, and heat endurance in industrial ovens. We can recommend the best synthetic base and adhesive for your particular needs. For example, our water-label material uses a high-cohesion food-safe glue so it won’t fall off a wet bottle.

-

Regulatory Compliance: If your products require special standards, we can meet them. GemmyLabel’s synthetic labels can comply with FDA and EU regulations (as mentioned above). We also support printing variable data, barcodes, or RFID if needed for tracking.

-

Dedicated Support: From the initial quote to after-sales service, we partner with you. We offer design assistance, prototype samples, and timely delivery. GemmyLabel is committed to customer satisfaction – we won’t consider the job done until your labels work perfectly on your lines.

FAQ: Why use GemmyLabel for synthetic labels?

Because we treat each project individually and have the technical know-how to deliver a robust, cost-effective labeling solution. Manufacturers trust us for large or small orders, for specialty films or stock materials. In short, we deliver custom-engineered synthetic paper labels that meet your exact needs.

Conclusion

In summary, synthetic paper labels provide a long-term, professional labeling solution for manufacturers. Their polymer films resist moisture, heat, chemicals, and abrasion far beyond what ordinary paper can withstand. They also offer superior print quality and endless customization. For virtually any industry – from automotive to food to electronics – synthetic labels ensure product information stays legible throughout the product’s life cycle.

By choosing GemmyLabel, you gain a partner who will tailor these high-performance labels to your exact specifications. With our advanced materials, strict quality control, and full customization options, your products will bear labels that survive any challenge. For durable, waterproof, and fully custom synthetic label solutions, contact GemmyLabel today. We’ll help you replace failing paper labels with reliable synthetic labeling that enhances your product’s quality and brand image.

Key Takeaways: Synthetic paper/film labels deliver unmatched durability, waterproofing, and print clarity. They work on any surface and under extreme conditions, making them ideal for industrial use. GemmyLabel specializes in providing these custom synthetic labels – meeting regulatory standards and quality requirements – so your manufacturing labels always perform as needed.